I got back into finishing the Technics 1200 in the last few days. I had been putting it off while waiting for parts, working on other projects or just procrastinating. However once I started again I finished in 2 evenings.

One of the problems with waiting as long as I did was the possibility of losing pieces and or just forgetting what went where. The good thing about this turntable is that there are so many pictures, forum threads, how-to's, documents and videos about it that as long as I had a computer near I could not get too lost.

I still wish some of the parts came with some form of instructions though. KAB has some so-so pictures on his site but nothing at all comes with the actual parts, such as the hinges or turret board. Even suggested wire routing, or a parts list or sequence of assembly. I am very mechanically inclined but even so. I also think I might not have received some of the screws with the hinges. I could be wrong about that but anyway I managed to find some appropriate bolts in one of my bins.

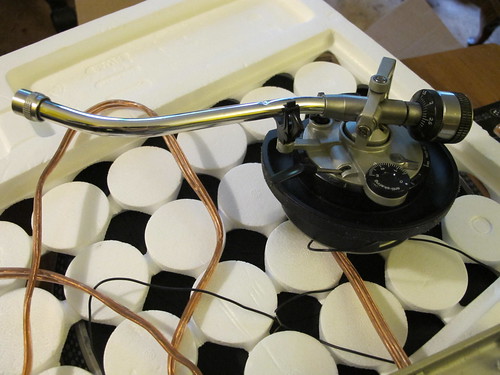

In the first pic above you can see the tonearm after internal wiring was updated with new Cardas 33g wire. I also added some cotton batting inside the arm as damping material to reduce resonance. The black stuff on the outside is heat shrink tubing to help play a similar role. However it looked ugly in that on the curves and ends it developed wrinkles. Pretty ugly and of probably very small sonic benefit, so I stripped it off.

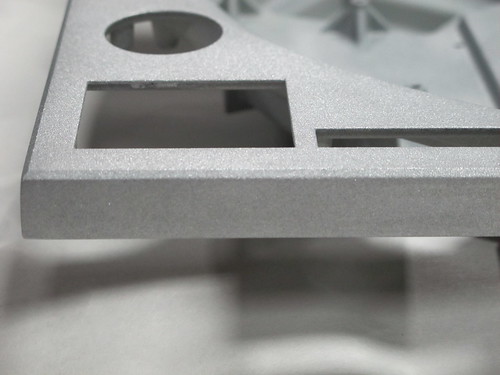

The second pic shows the underside of the arm with the new terminal board attached. The tonearm wire meets the external wiring at the 5 pin strip here. This replaces a small printed circuit board that Technics originally installed.

Some instructions online make things look dead easy. Easie-Peasie in fact if you can believe the English bloke on YouTube who has lots of videos on the 1200. He describes how to thread the 2 base parts together using the 0 marking on the height adjustment scale as a guide and he gets it right first try in a few seconds. The Technics Service Manual says use the 3 (scale is from 0 to 6 for millimetres of height adjustment) as your starting point. I tried at least 5 or 6 timed before I got it right, and using the Technics method, not his.

The next photo just shows an alternate view, plus the record weight I had powder-coated at the same time. Below that is a top view of the new KAB interconnect board. This attaches on the same bolts (longer ones than stock) as the right side hinge. This external connection enables you to use your choice of RCA cables. I don't particularly like the wires being as exposed as they are, but I used a bit of tape to anchor them somewhat, but I think I will also make a small clamp or sleeve to attach to the underside of the table to protect the wire.

Another thing I supplied myself was some adhesive backed felt from a fabric store. This went under the pitch control slot and directly on top of the control itself and acts as a dust shield. Another piece goes on the underside of the knob itself.

And finally the end result!

I am practically ecstatic with how good it looks. It also works great (but see below) and sounds terrific. I still have to fine tune a few things and there are still a couple of issues.

The cartridge position has to be checked, the VTA (tonearm height) and the anti-skate verified. One of the issues is that the tonearm rest does not fit this arm well. The mount for it on the old arm was just slightly different. I had to gently ream out a bit to make this fit, and I don't have the right nut or spacer for it. It also won't quite clamp the arm properly. I think that just maybe it was not from the same model of turntable. With the damage that was done to the old tonearm I would be surprised if this was also replaced at some point.

The bigger concern is a bit of speed instability. The pitch slider is supposed to completely lock the speed at the centre setting. It adjusts speed up or down by 8% over the range. When I first turn the table on it sometimes seems spot on, but other times runs very fast in the middle of the scale. It can be zeroed at a postition just off centre but that bugs me. When I have played a side or 2 it seems to stabilize and zero means zero. I have more testing to do, and some troubleshooting.

A lot of my stuff has been coming courtesy of KABUSA, just so you know.