For the purposes of this post I am using a basic Sanyo TP-1010 belt drive turntable. It's a belt drive semi automatic model with pitch controls for both speeds. It has fine tuning controls visible externally and other controls inside. It's pretty typical or similar to many models from numerous brands.

The external fine controls are adjusted by thumbwheels to the right. The internal or gross controls can also be accessed externally but they are under the platter and not visible until you remove the mat or platter.

Anyway, the speed controls will get contaminated with dust or corrosion over the years and this will lead to them not working properly. The result is that the turntable will not run consistently at the correct speed. Cleaning them often solves this.

Typically I use a product called Electrosolve from MG Chemicals. Others might recommend Deoxit but I find it too expensive and not necessarily any better.

When using this or similar products you give a brief fraction of a second shot into the control and then turn the knob or wheel through the entire range multiple times, like 20 or 30, to distribute the cleaner and effectively scrub the path of the variable resistor.

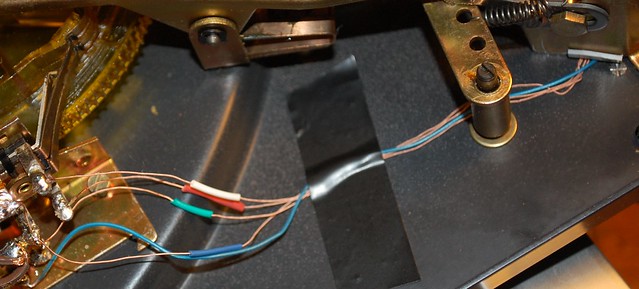

Sometimes it's easy to see where to spray the cleaner and in this case it's pretty obvious. Other times, and especially on more modern equipment, it's less clear as the parts are better sealed. Essentially you need to look for openings or gaps in the housing of the variable resistors. Look at where the red tube is directed.

The devices shown above are the fine tuning ones. The gross controls are on a different printed circuit board. They don't need cleaning as often as the others but sometimes they need it too. They must be adjusted with a small screwdriver 🪛 and it's best to take note of where they are pointed and return them to the same spot or as close as possible. Take a picture to help with this.

The gross adjusters are helpful if you can't get the fine variable resistors to stabilize the speed at or very close to the center of their range. Having them accessible from the top is really handy for this. Otherwise you often have to get creative with some way to support the turntable high enough to get the screwdriver underneath. Blocks of wood, bricks or large soup cans are things I see people using. I found an old magazine rack that works well for this. I don't need it for this job but I will try to get a picture of it later to add to this to give you ideas.

If you find that you can't get the top mounted fine adjustment VRs (variable resistors) to bring the strobe dots to a stop at the center of their range, try the gross ones. It might only take a tiny nudge with the screwdriver to bring the strobe to a stop but first move the fine adjustment to the middle of its range.

In this turntable there are 4 VRs, but some only have a single fine VR and 2 gross ones. In some there might be no external control at all. And then of course there are turntables that have none. Speed adjustments on those might still be possible but that's another topic.

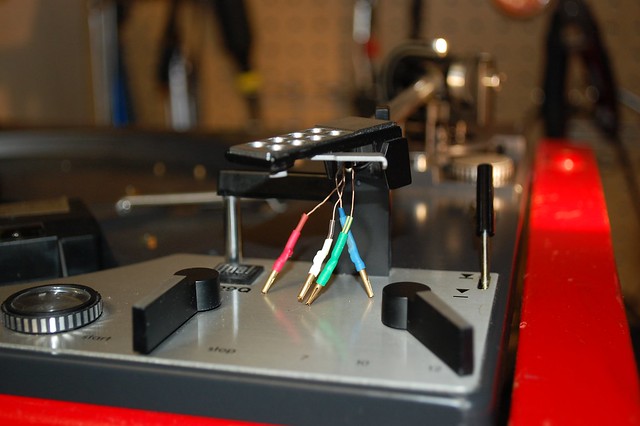

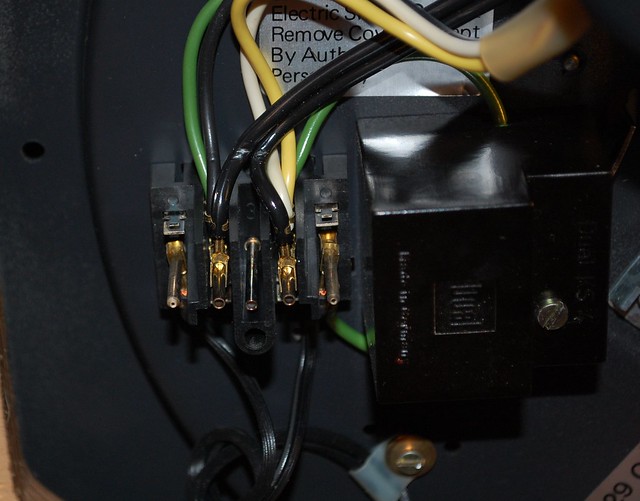

Edit: it's been brought to my attention that I should mention cleaning the switch(es). So here we go.

There are 2 switches in this one. One stops or starts the motor and the other handles the 33 to 45 speed change. In many belt drives the speed change is purely mechanical, as in a lever of sorts moves the belt from one part of the motor pulley to another of different diameter. Not the case here.

The speed switch is in the lower left and the motor switch is the red and black thing further up the picture.

Aim your spray as shown and again manipulate the switch a couple of dozen times.

While you at it, it's a good time to get some oil into the motor and the spindle. In this case I'm using Triflow. There are other choices but lighter is better than thick stuff in my opinion.

Don't get oil on the pulley itself or at least clean it afterwards.

I also mentioned that stand that I sometimes use, though in this case it wasn't needed. It's actually a wooden magazine rack I found that had a canvas sling. Without the cloth in the way it's very handy for holding the turntable up high enough to get easy access. A mirror underneath can help too. Look around and you might find other ideas.